1964-70 Mustang

Base Price:

$13,995.00

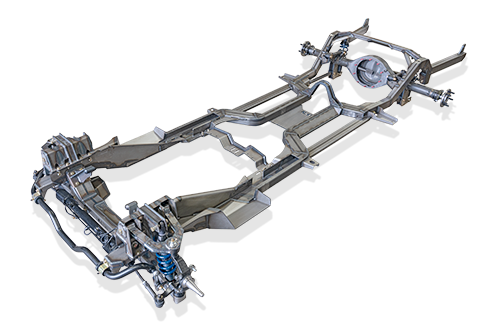

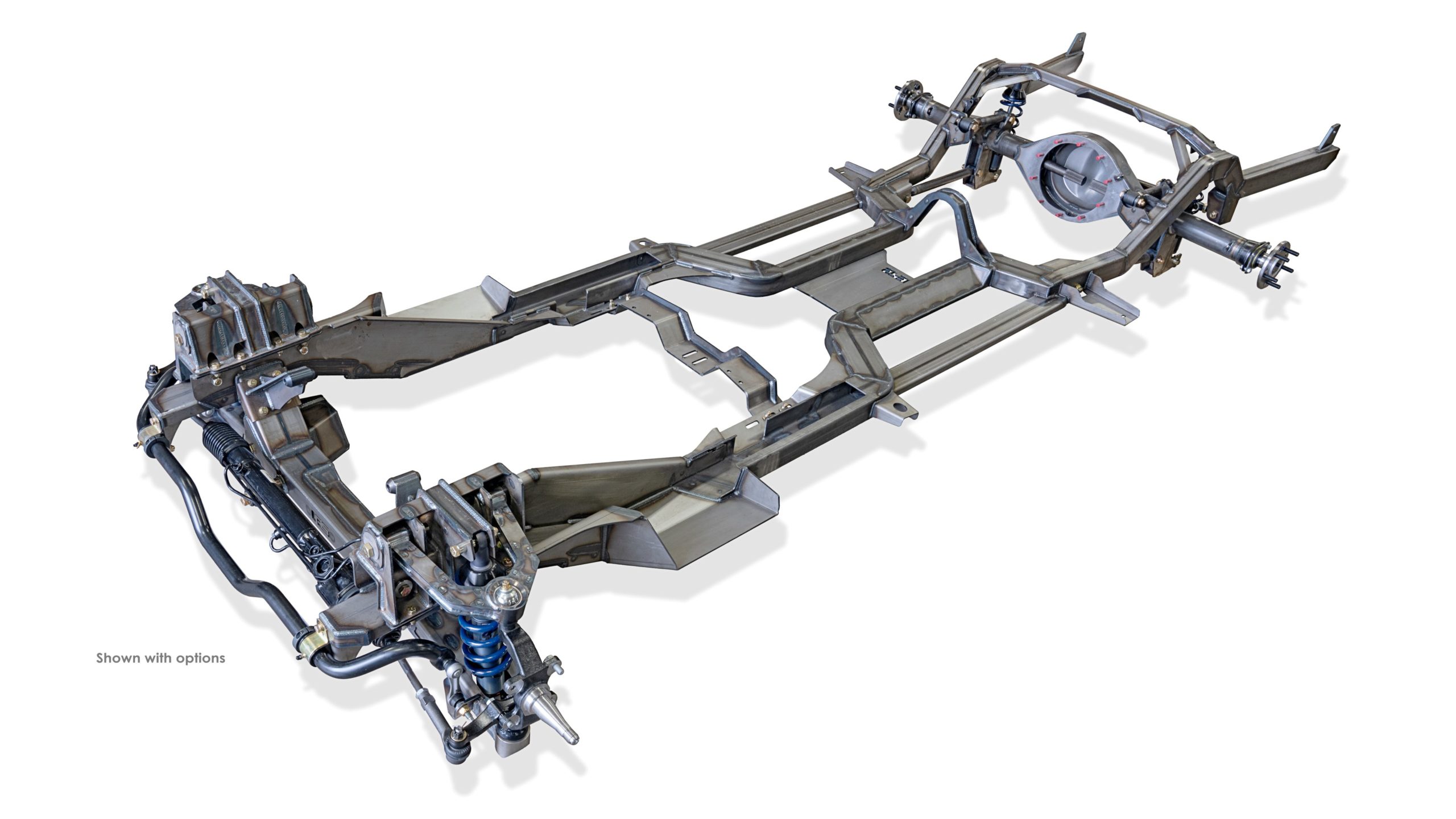

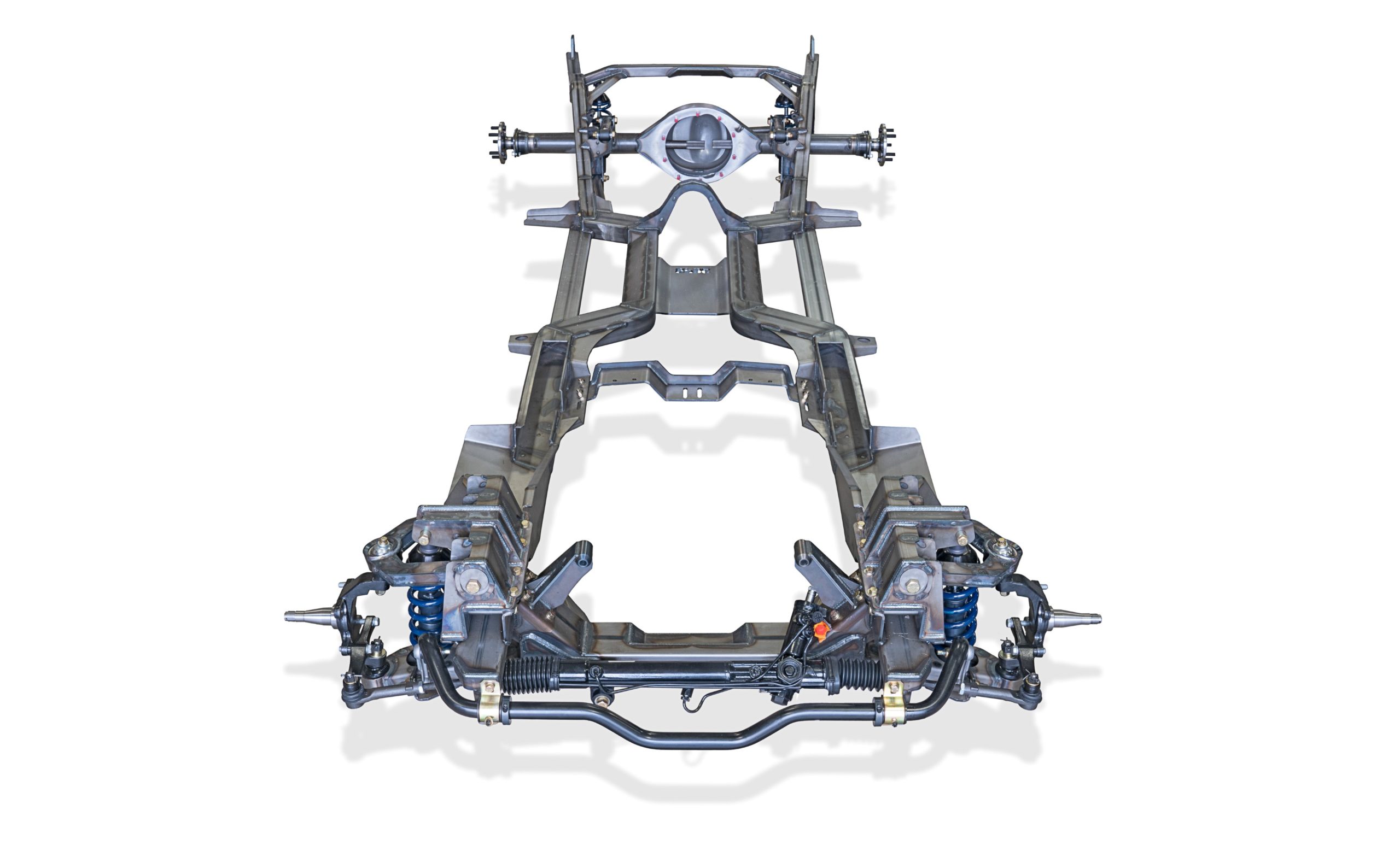

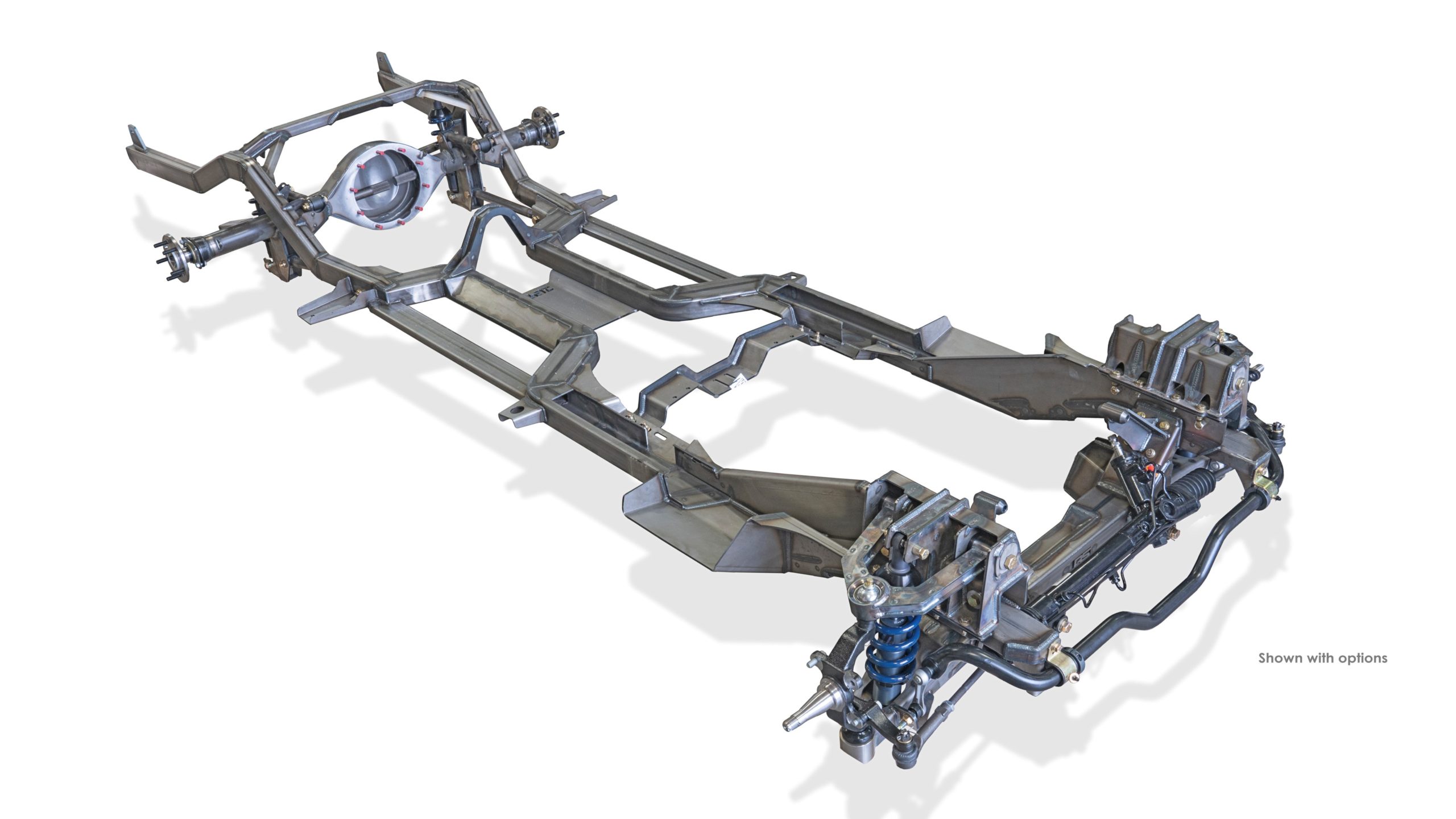

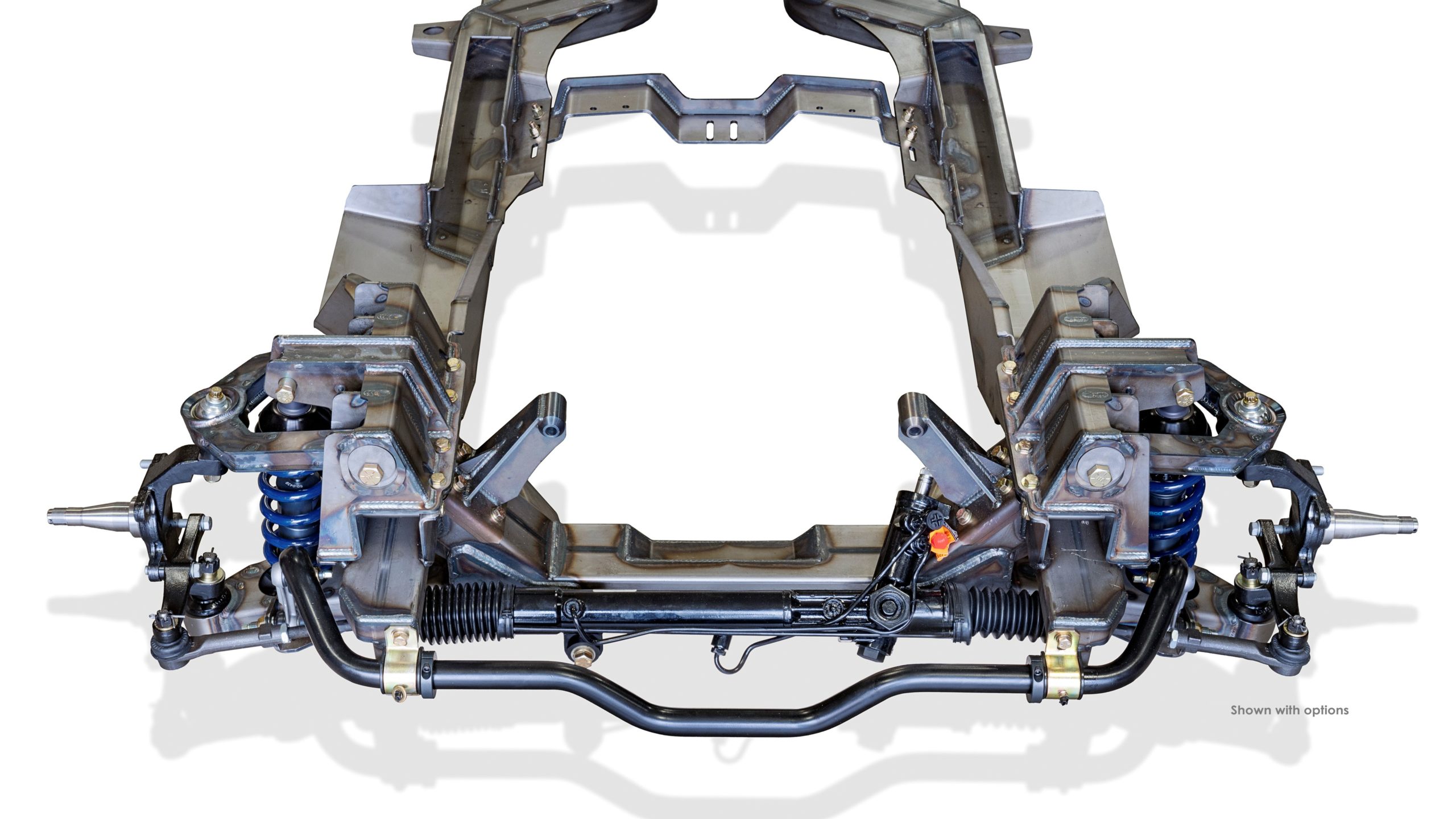

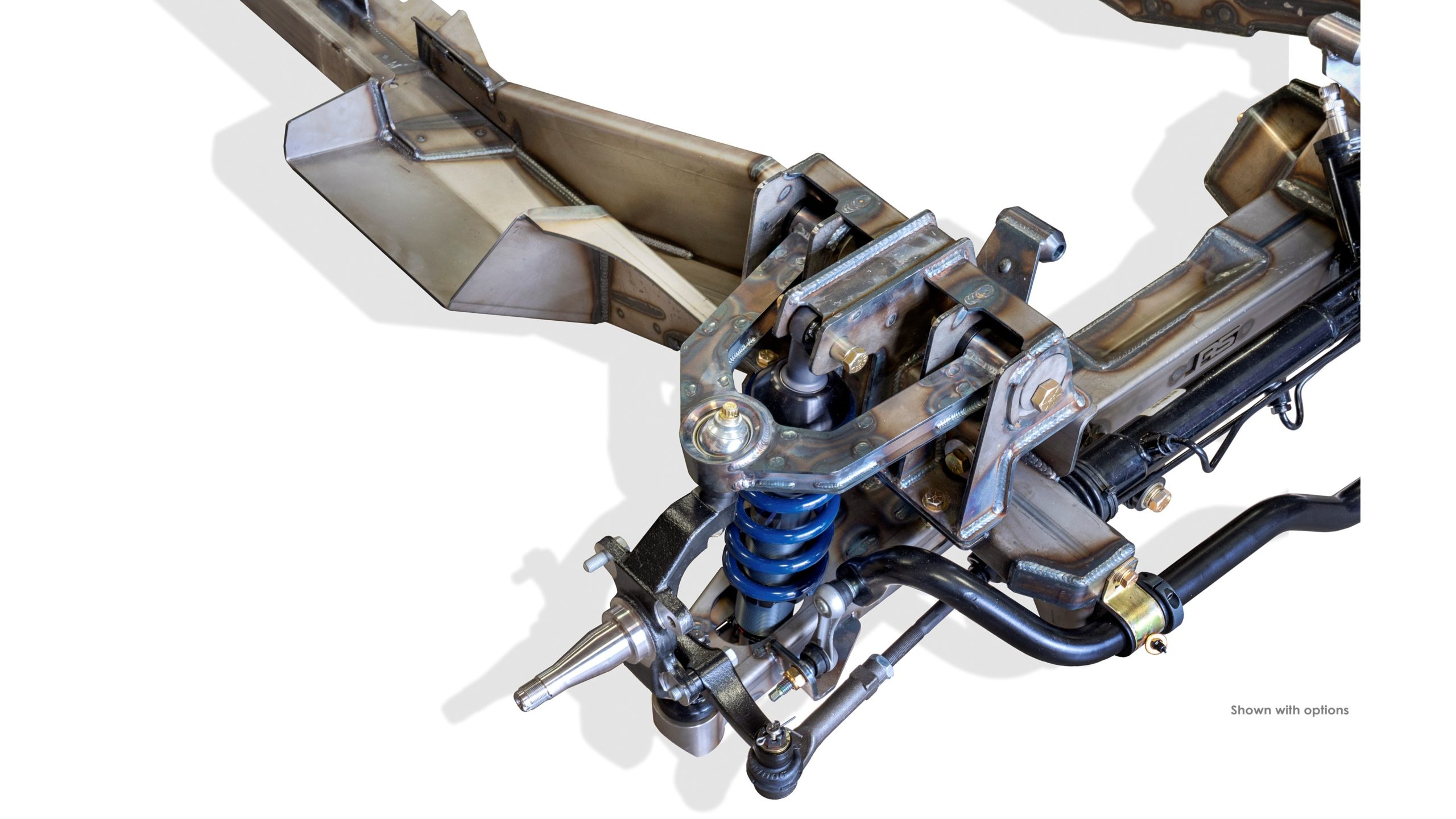

- 59” Front track width with spindles and brake packages that accept wheels as small as 15”,

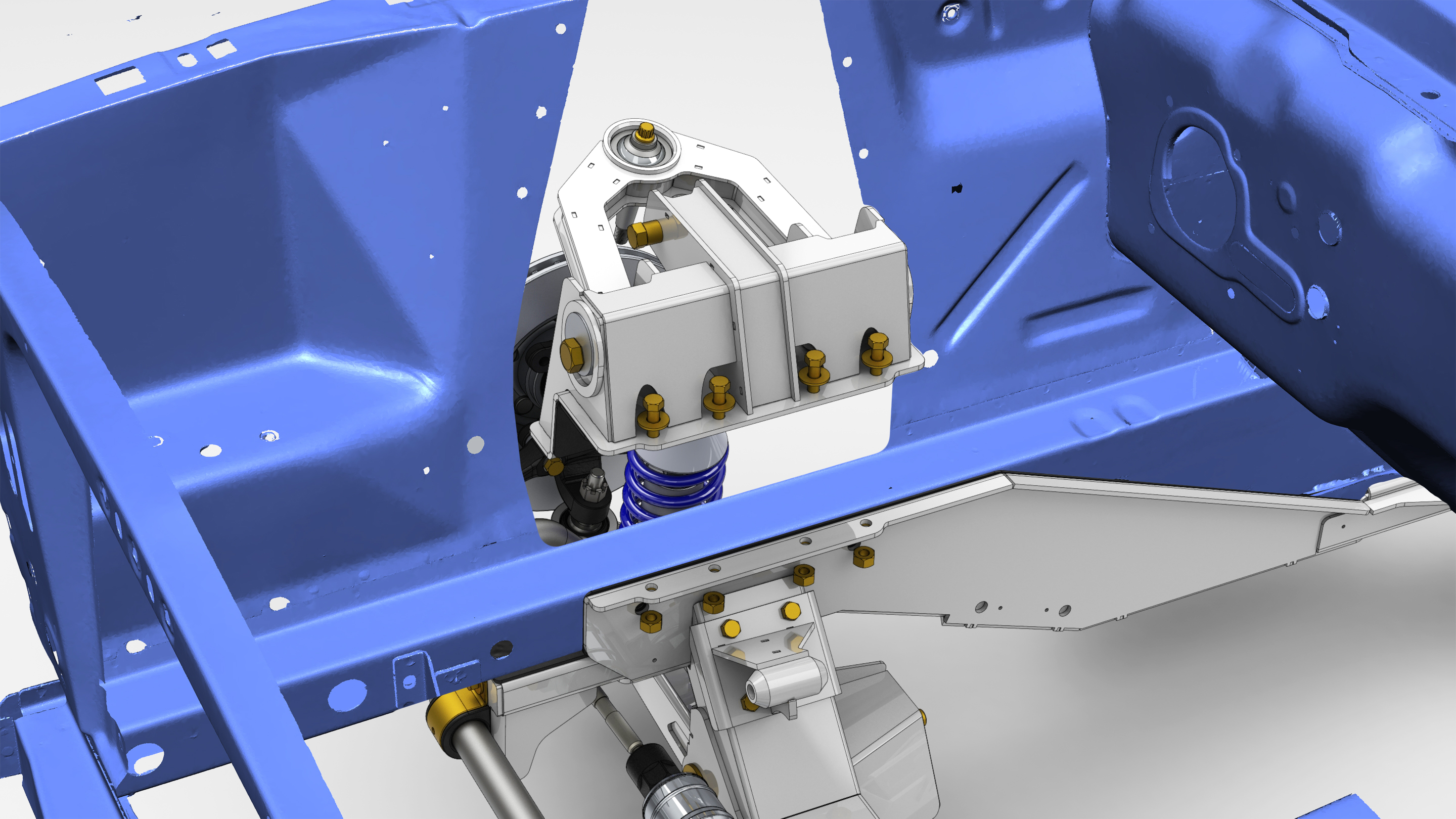

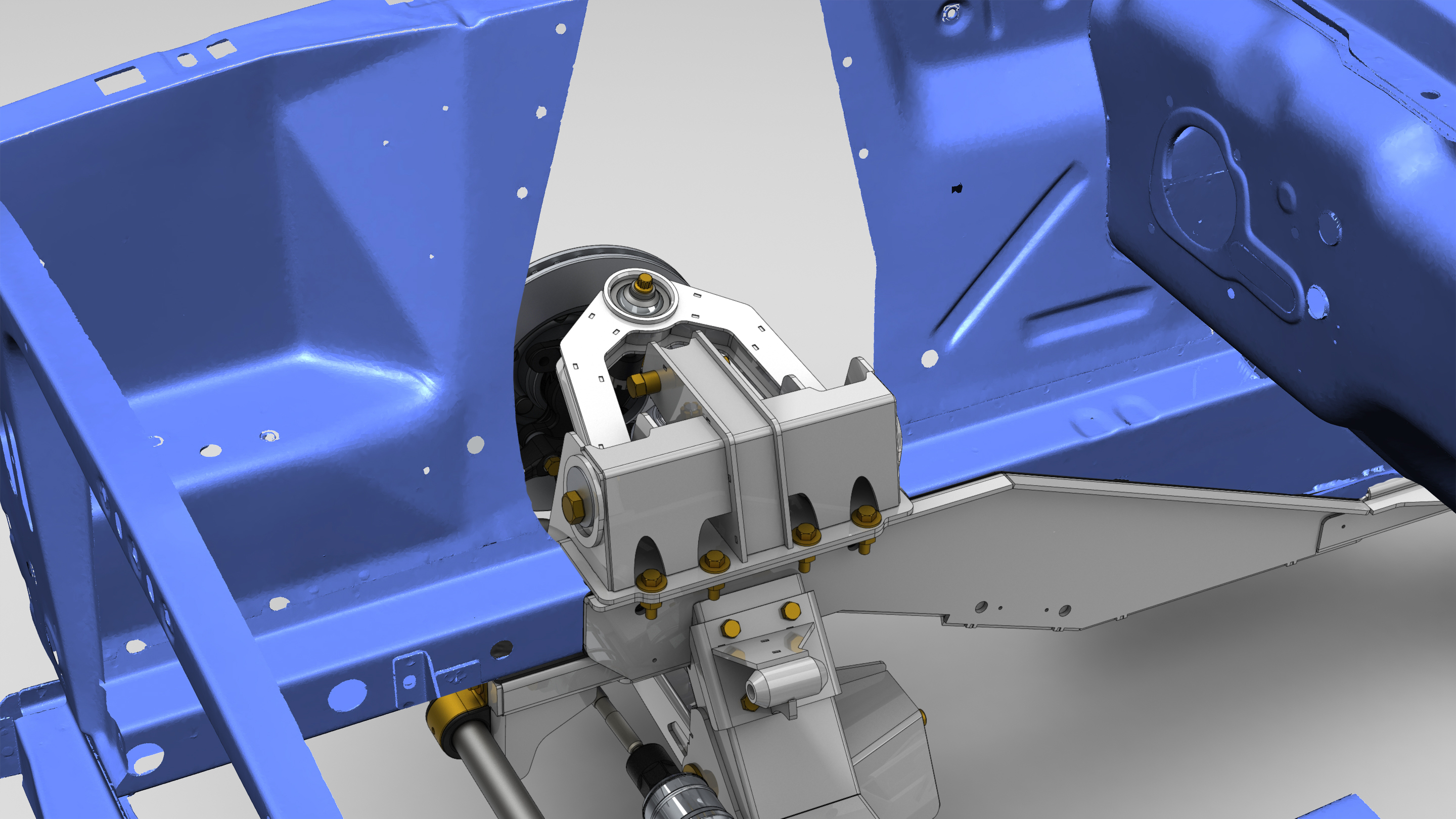

- 2 Piece SPEC IFS crossmember bolts over existing sub-rails.

- Fuel tank mounting footprint has remained unchanged, so any OEM replacement or drop in aftermarket tank can be used.

- Driveline positioned so that the Tremec T56, TKO 500/600, and 4L60 transmissions clear the factor transmission tunnel without modifications. T56 and TKO shifter aligns with original shifter opening on the factory tunnel.

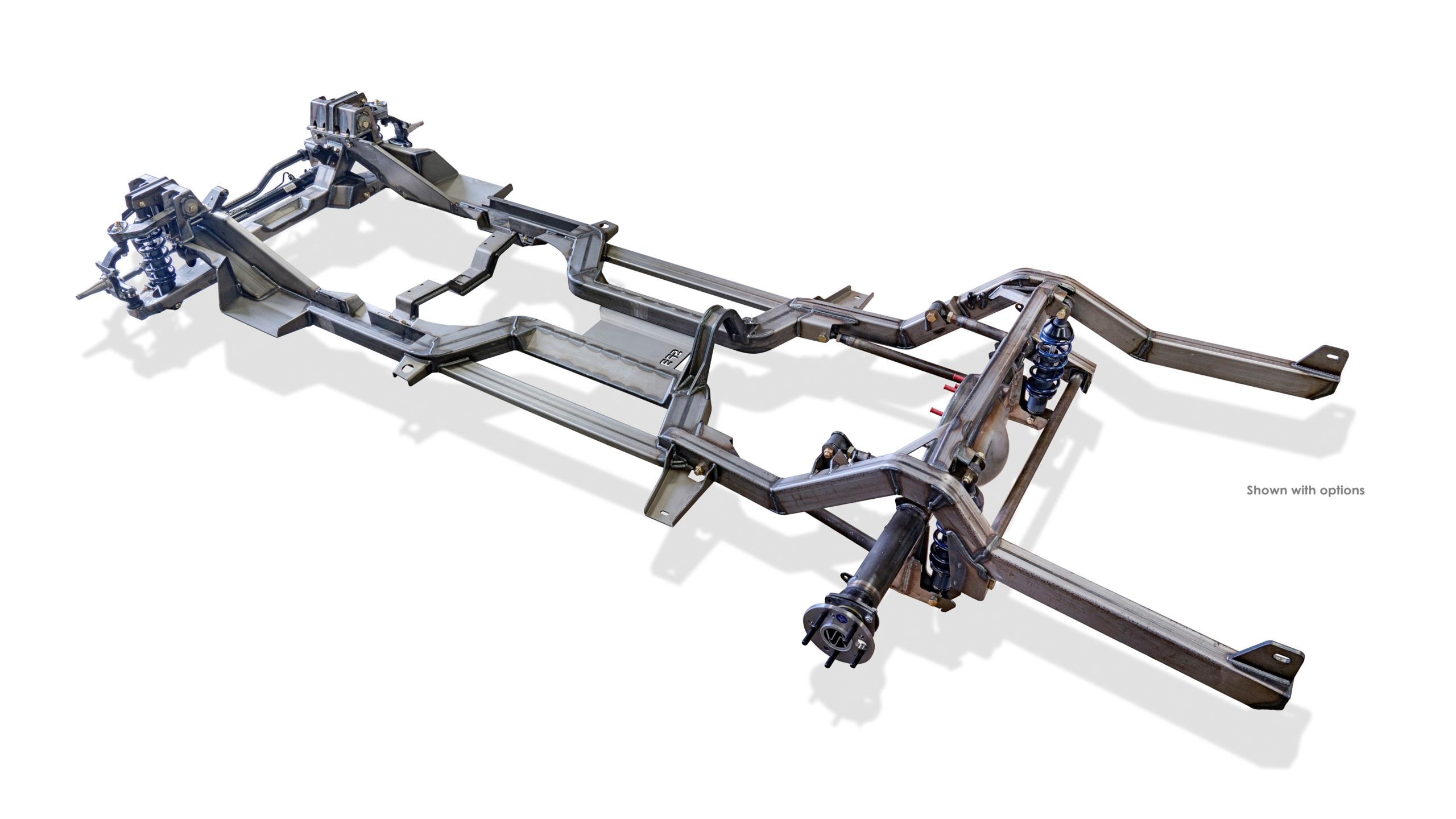

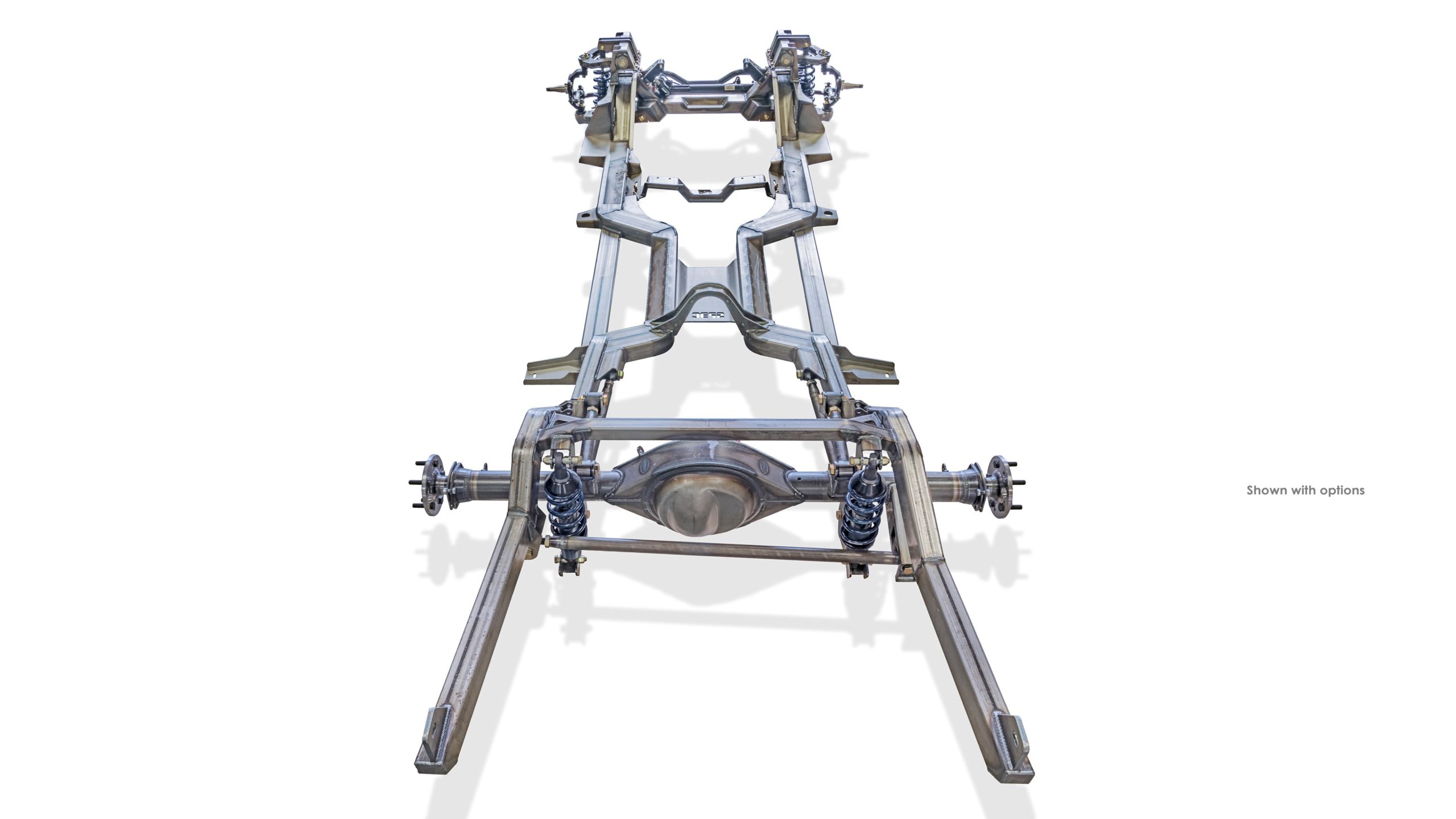

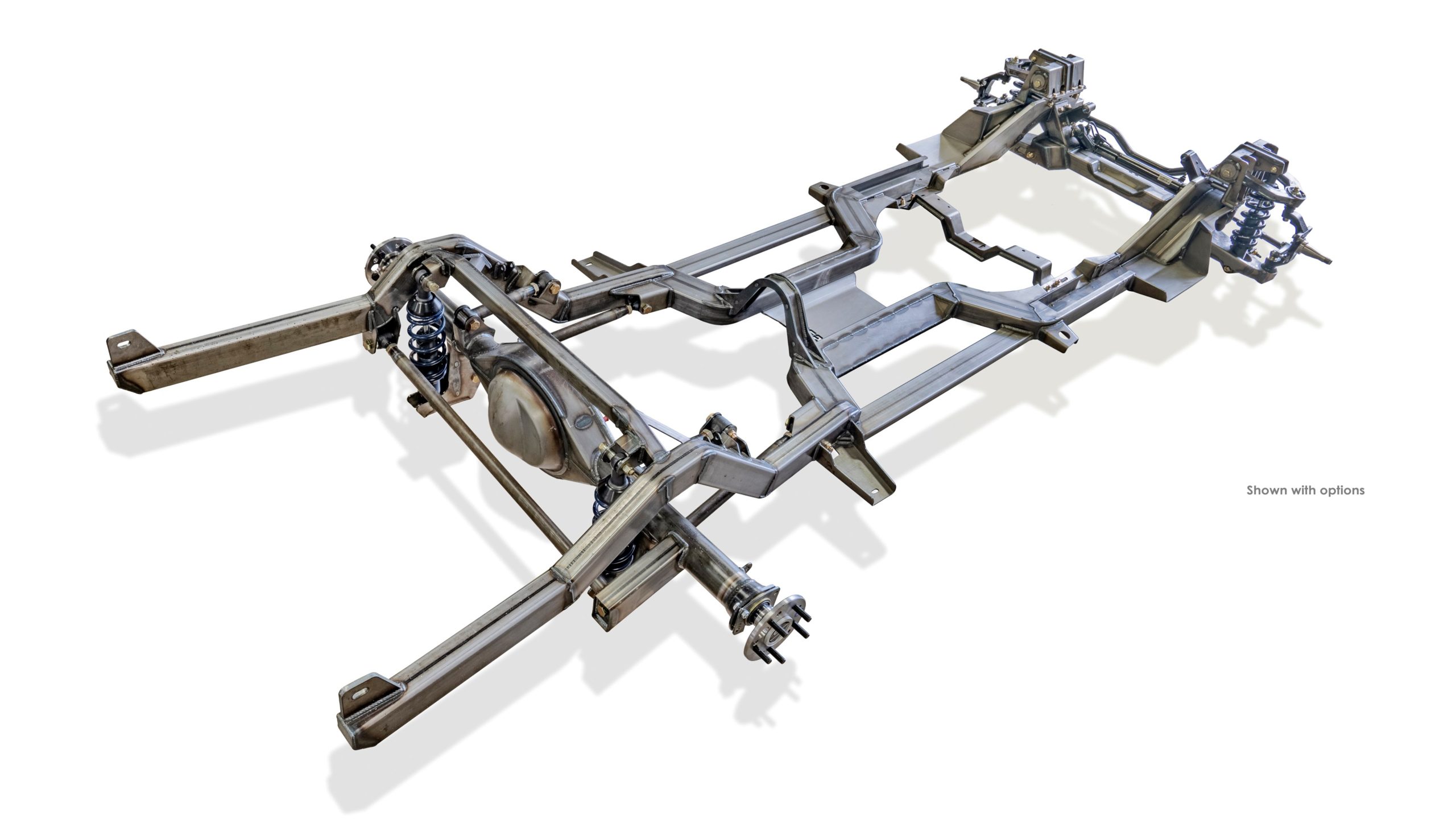

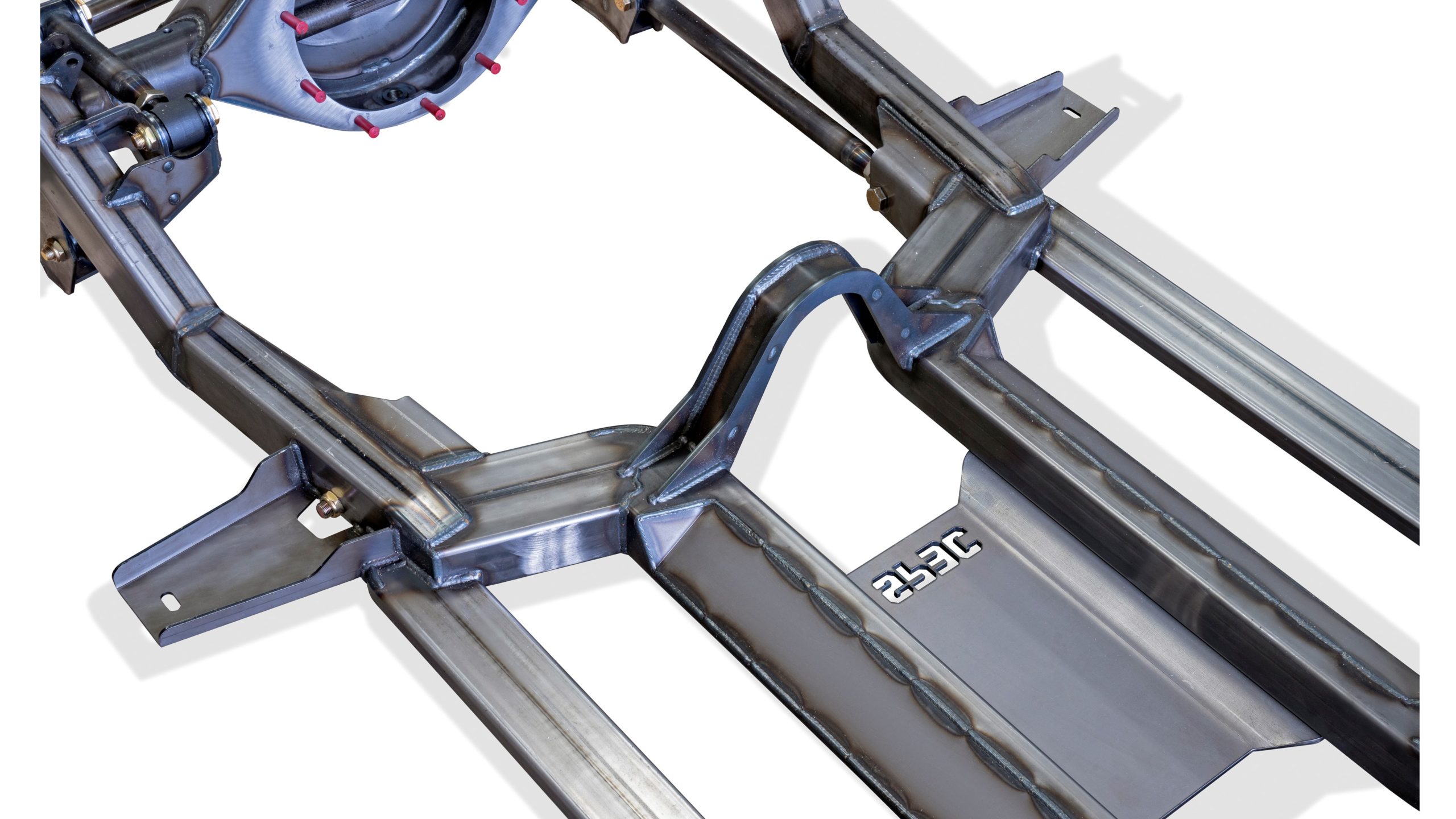

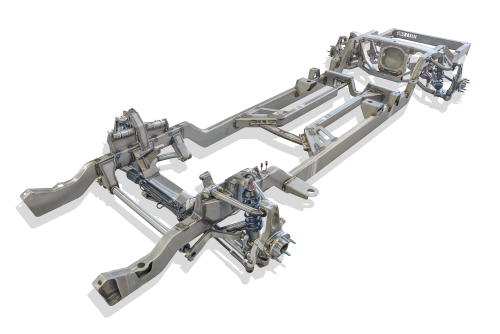

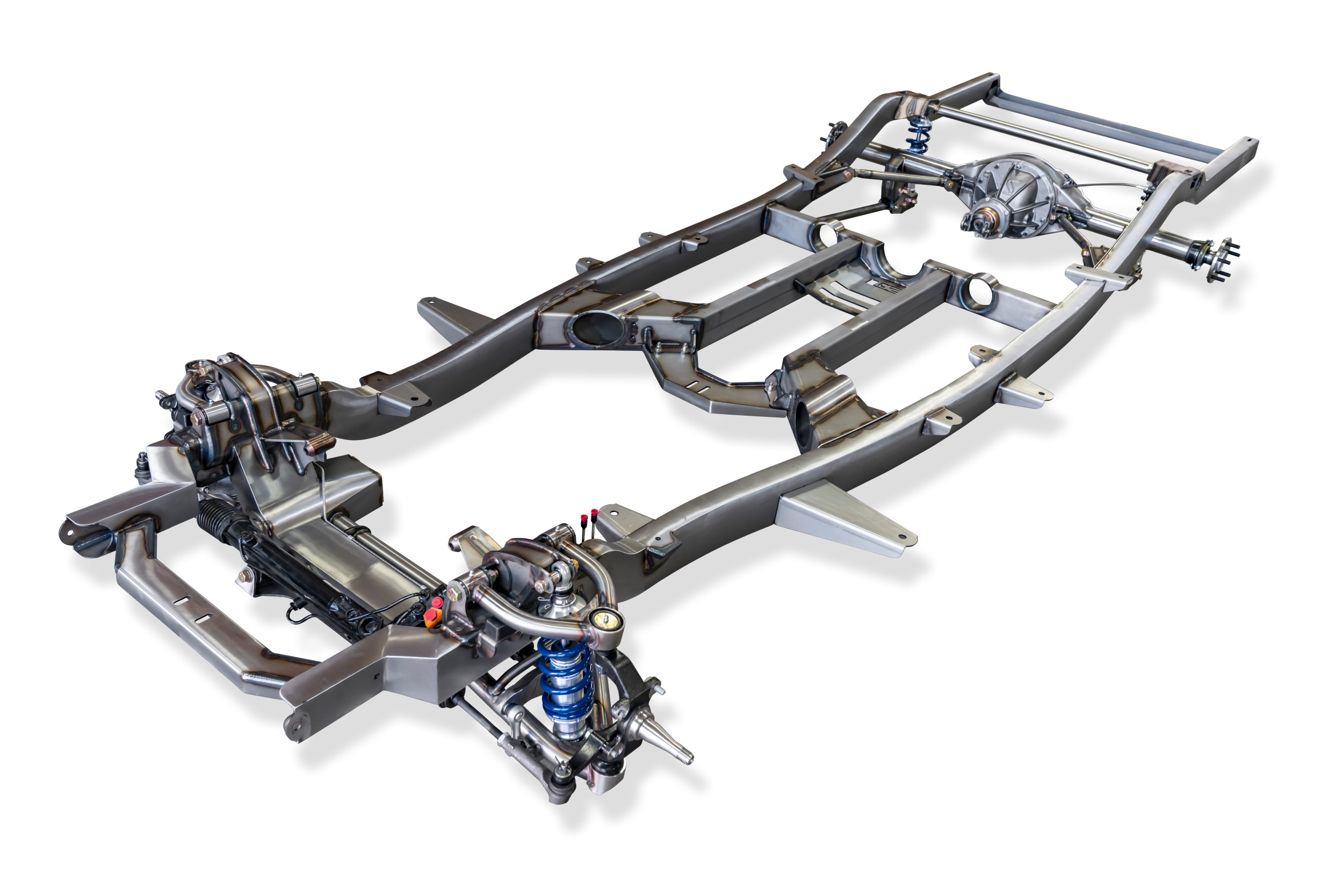

- Full chassis layout using Roadster Shop SPEC laser rails creates the easiest and firmest chassis system for early Mustangs.

- Proprietary modular front clamping rail system allows the IFS to clamp onto the factory subframe rails with minimum modification.

- SPEC IFS suspension geometry, designed around a SLA double wishbone front suspension eliminates the antiquated strut-based system

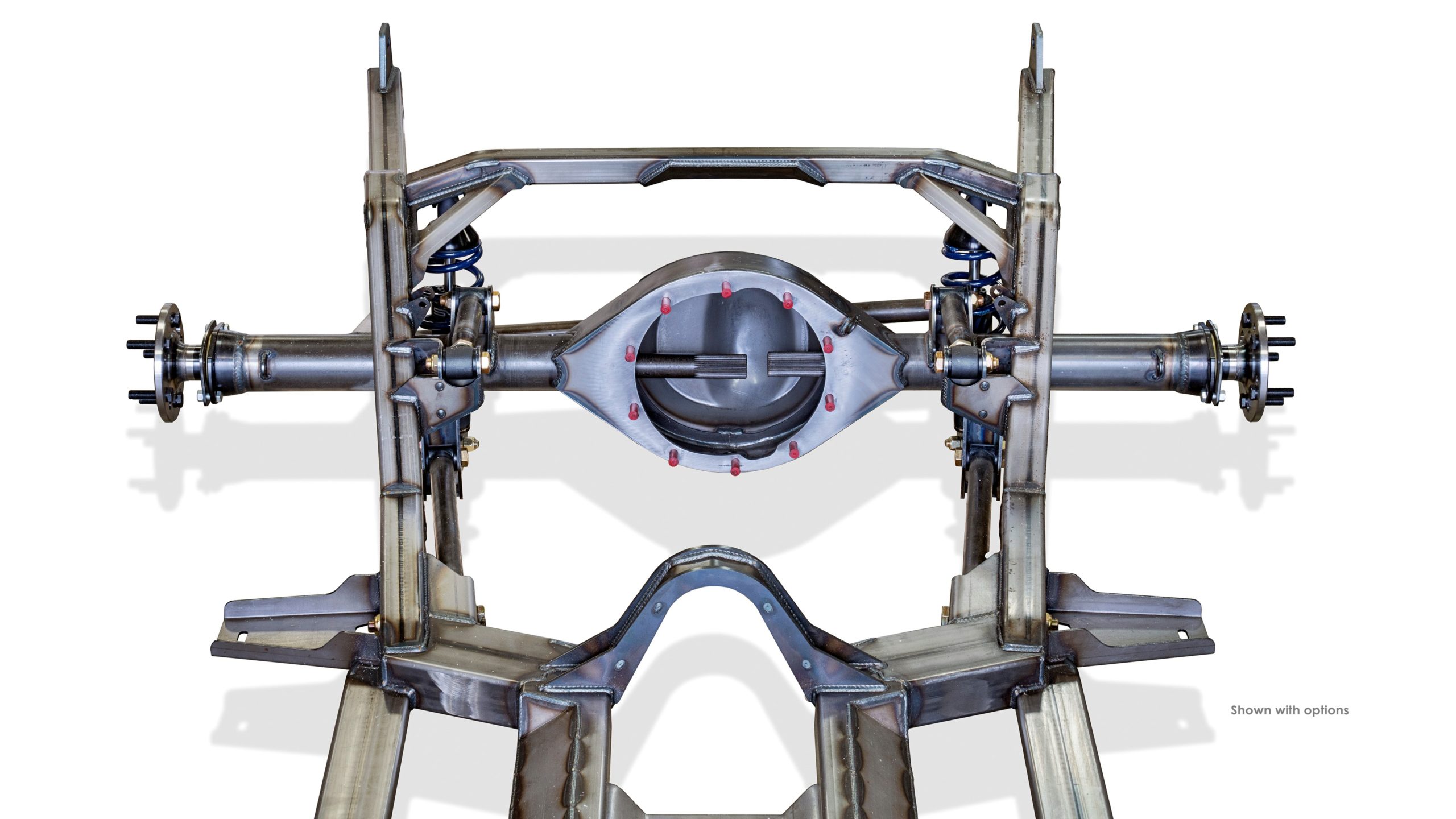

- Parallel rear 4-link suspension with a 5th panhard lateral link allows smooth and controlled rear travel while requiring no floor modifications.

- Exhaust routing provisions for up to 2.5” dual exhaust.

| Bolt On - No Modification Needed | |

| Floor Modifications Needed | |

| Bumper Bracket Modifications Needed | |

| Independent Rear Suspension Available | |

| Adjustable Track Width | |

| Powder Coating Available | |

| Mandrel Bent Tubing | |

| Welded Tubing | |

| Clearance for up to 3" Exhaust | |

| Pro Spindles | |

| Late Model Corvette Spindle | |

| Chrome Control Arms Available | |

| Free Shipping |

Description

Any builder will soon find the factory Mustang unibody and suspension design riddled with inherent issues when trying to bring an early pony car up to today’s standards of ride quality and comfort. There have been many attempts to fix these issues with braces and cradles and crossmembers, and connectors which all seem like one band aid fix upon another. The original antiquated steering is top of the list when it comes to parts needing to be updated. Steering rack conversions are available but offer sub-par geometry and ackerman angle with little to no improvement over factory steering.

The factory shock towers make for an extremely tight engine bay and limit suspension geometry. Bolting new components into factory mounting locations (designed 50 years ago) offers minimal performance improvement, and offers mainly only cosmetic appeal.

Until now, there has never been a complete solution. Roadster Shop saw the need for a complete, simple, single platform in a sea of aftermarket parts and pieces.

With many obstacles to overcome, a complete chassis was designed with the bolt-in ease of installation. The channeled front frame rail design and bolt on upper suspension mounts are engineered to fit up to the existing factory sub-rails and inner structure and bolt in place. Simply cutting off the flanges on the factory inner and outer sub rails and welding of the seam is all that is required to create the flat surface for the IFS to mount over. The factory shock towers can be retained or removed at the builder’s discretion. The factory floor requires no modifications as the chassis bolts in place through 6 additional bolt in body mounts utilizing stock mounting locations already within the body, and 2 additional body mounts that simply require drilling holes to mount.

A Mustang specific version of the SPEC IFS has been designed to work with the narrower track width of the stock mustang and allow for “off the shelf” wheel fitments. The new crossmember was engineered to work with a wide variety of engine packages.