1949-51 Mercury

Base Price:

$16,995.00

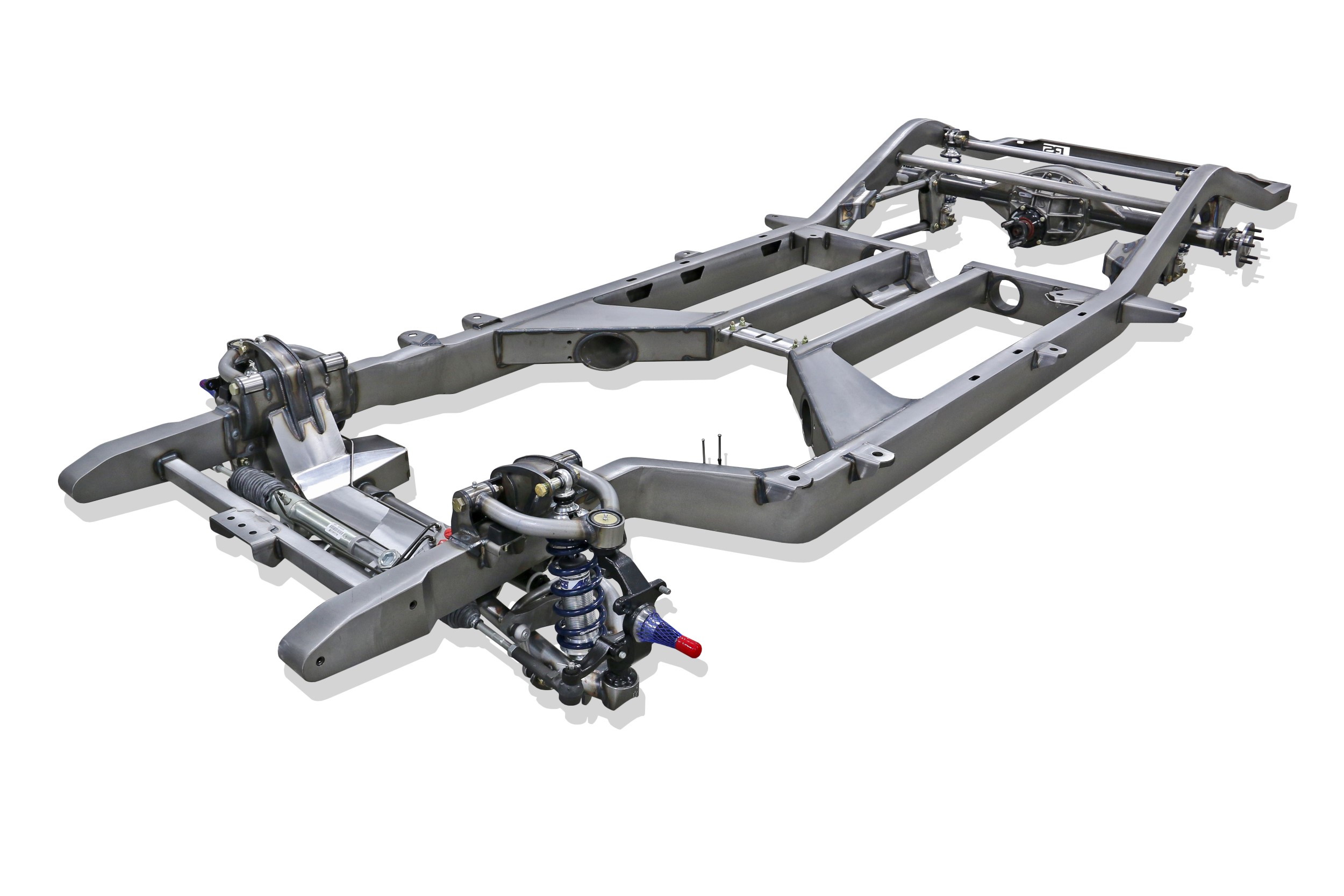

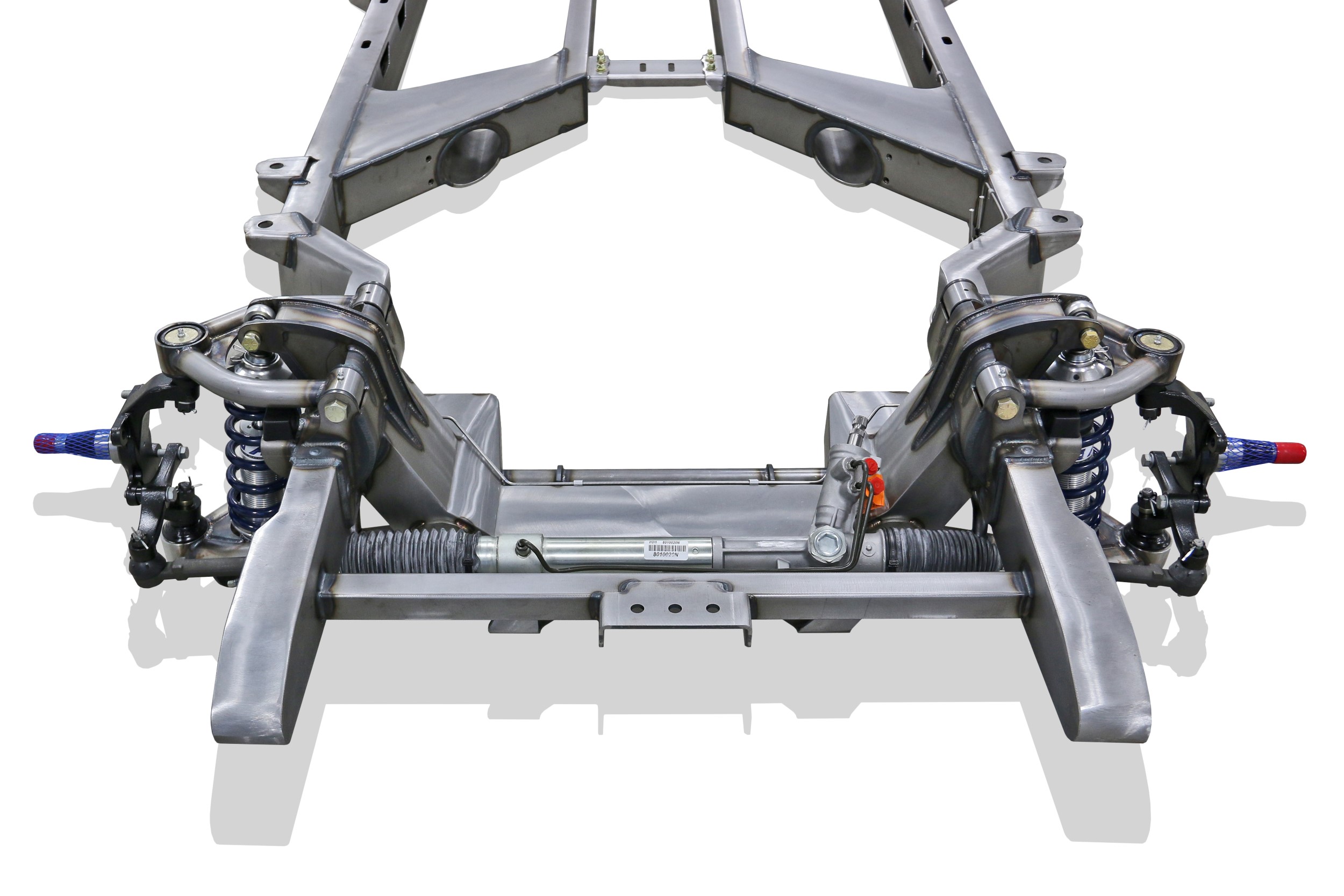

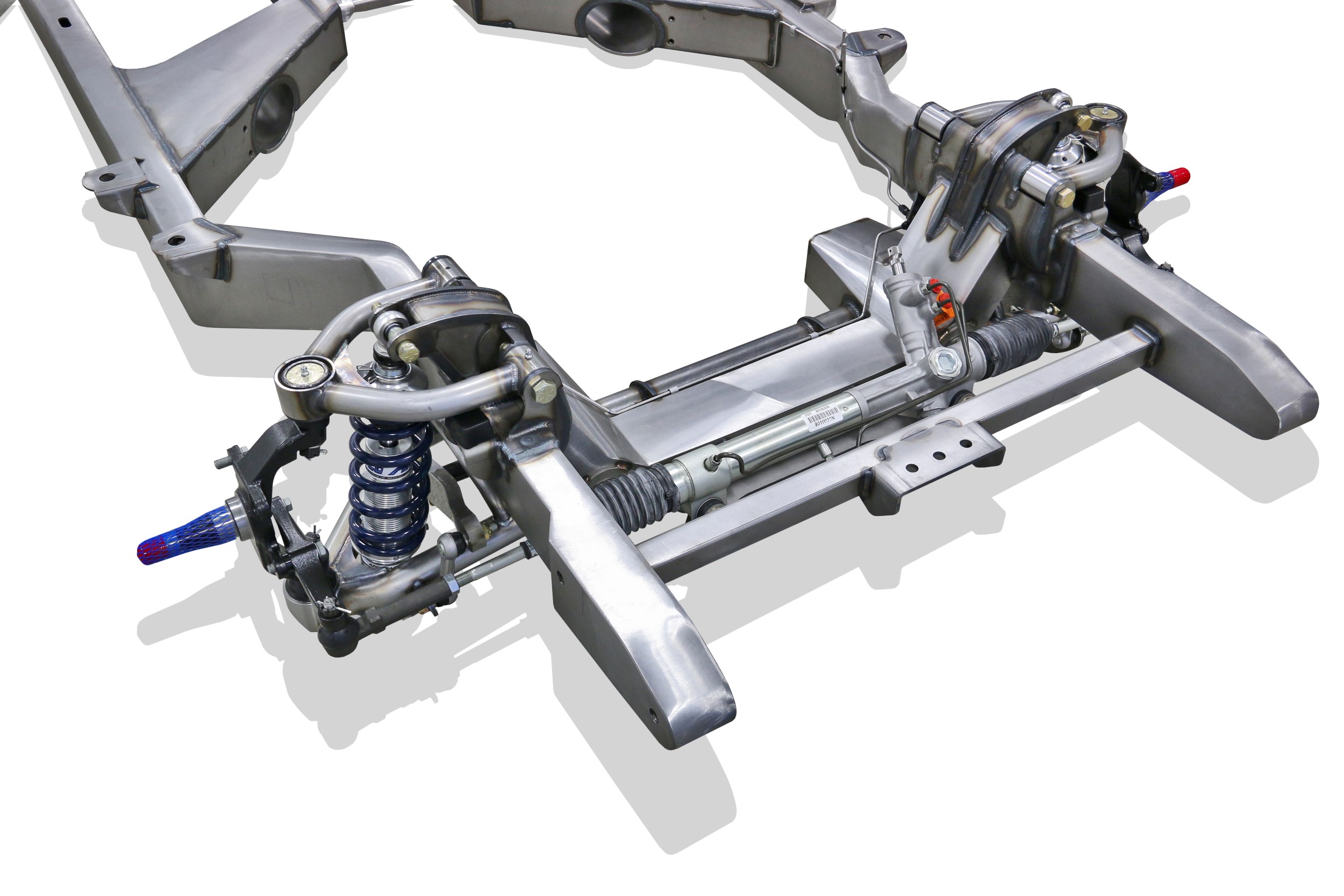

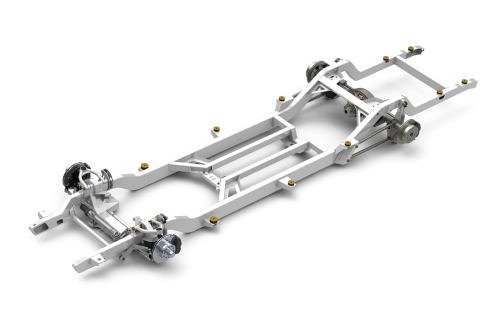

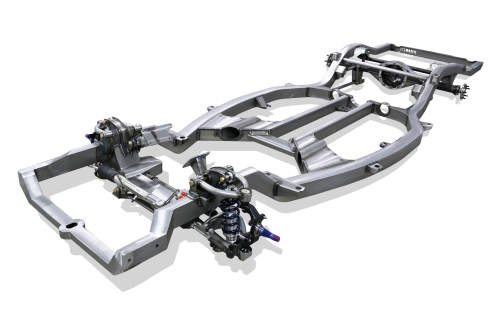

- Roadster Shop REVO IFS (54.75″ Track Width)

- Front mounted power rack and pinion steering

- Wilwood forged Pro Spindle with steering arm

- RS SV by Fox fixed valve coilovers

- Motor mounts for SBC, BBC, or optional LS motors

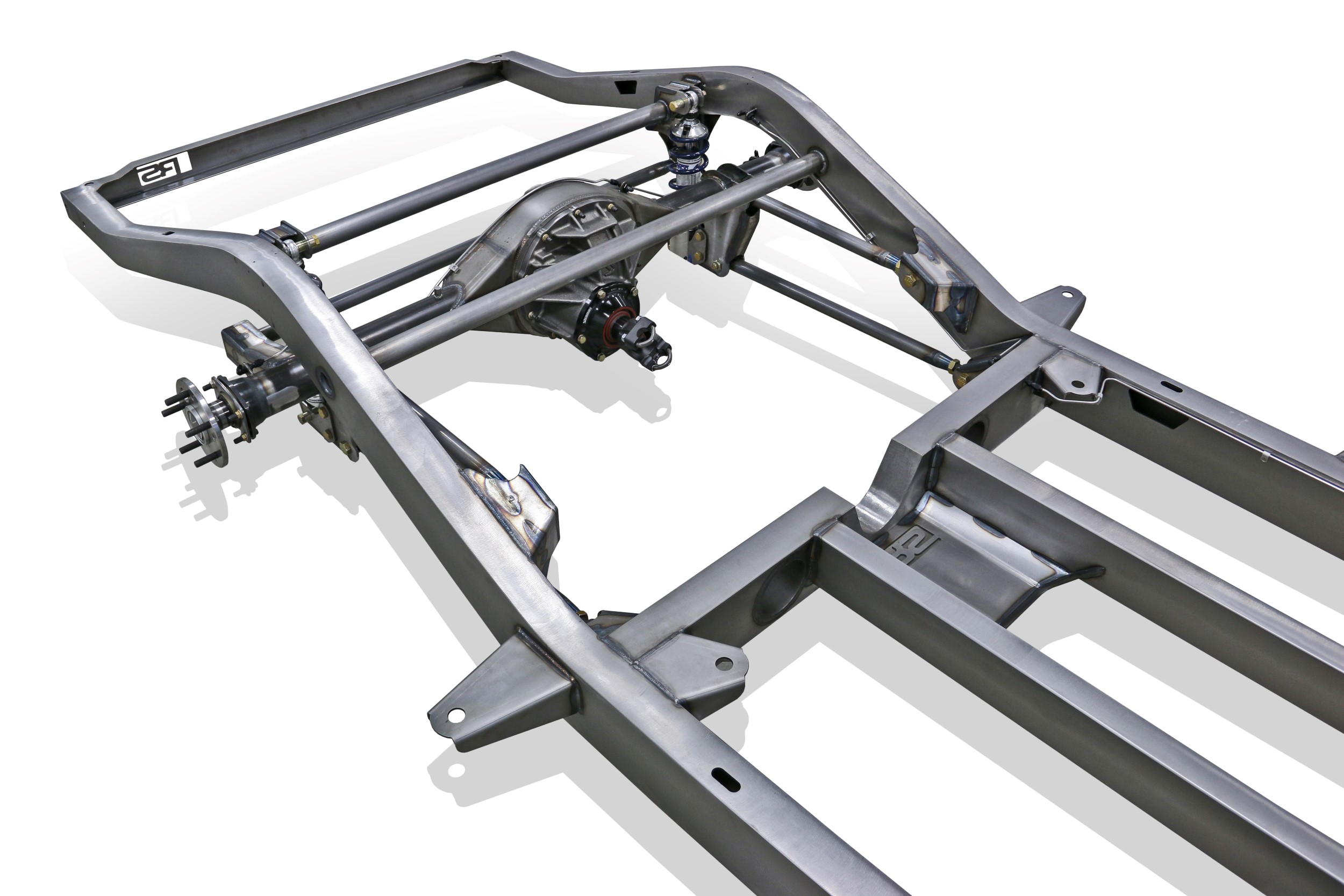

- 10 gauge, fully boxed, 4″ x 4″ fabricated frame rails

- CNC located factory mounting points for body , bumper, and core support

- Fully fabricated and tig welded center crossmember

- Exhaust clearance for up to 3″ exhaust

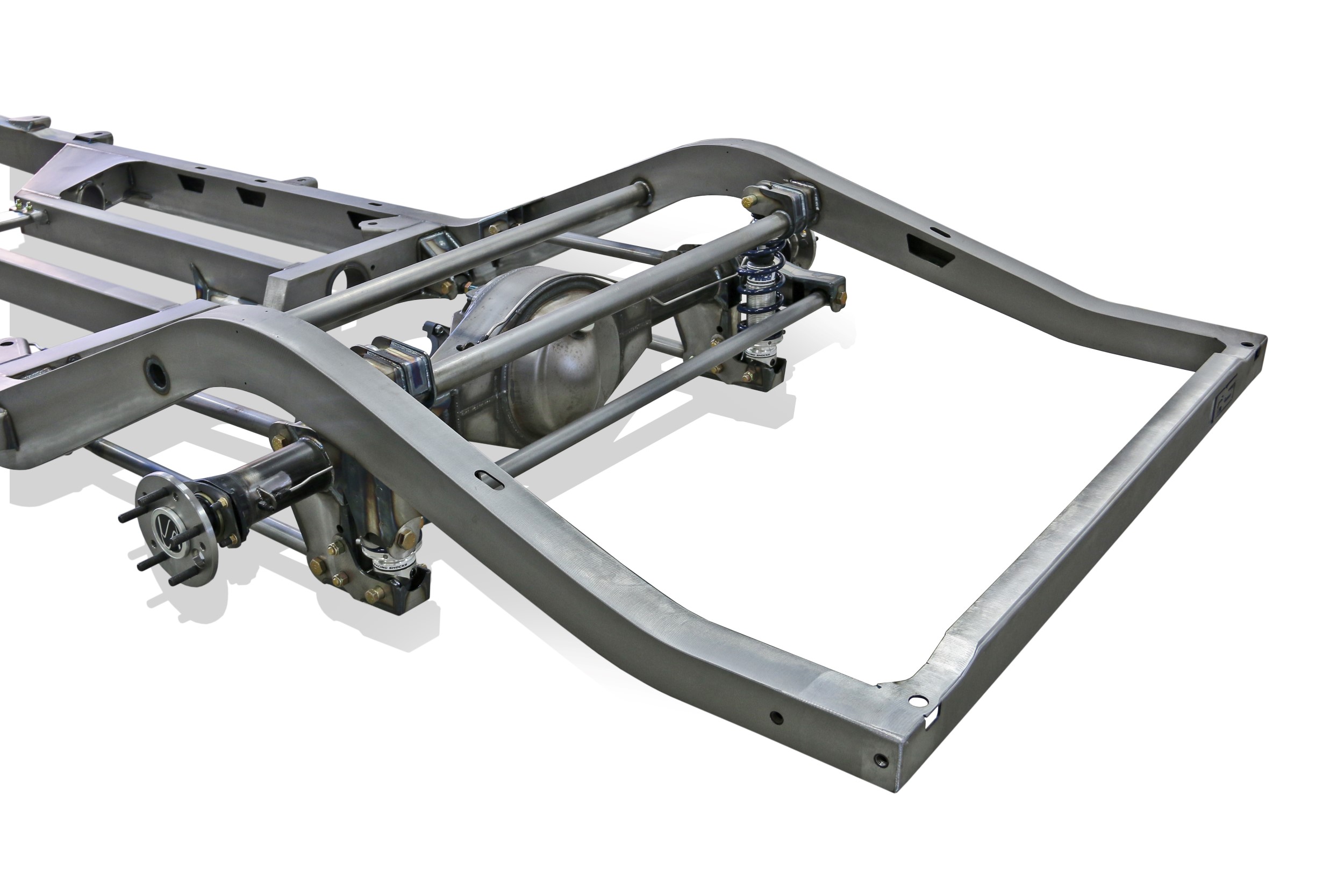

- Triangulated 4-bar rear suspension with RS SV by Fox fixed valve coilovers

- New Ford 9″ rear housing with 31 spline axles, 60″ track width

- Double sheer mounting on all load bearing components

| Bolt On - No Modification Needed | |

| Floor Modifications Needed | |

| Bumper Bracket Modifications Needed | |

| Independent Rear Suspension Available | |

| Adjustable Track Width | |

| Powder Coating Available | |

| Mandrel Bent Tubing | |

| Welded Tubing | |

| Clearance for up to 3" Exhaust | |

| Pro Spindles | |

| Late Model Corvette Spindle | |

| Chrome Control Arms Available | |

| Free Shipping |

Description

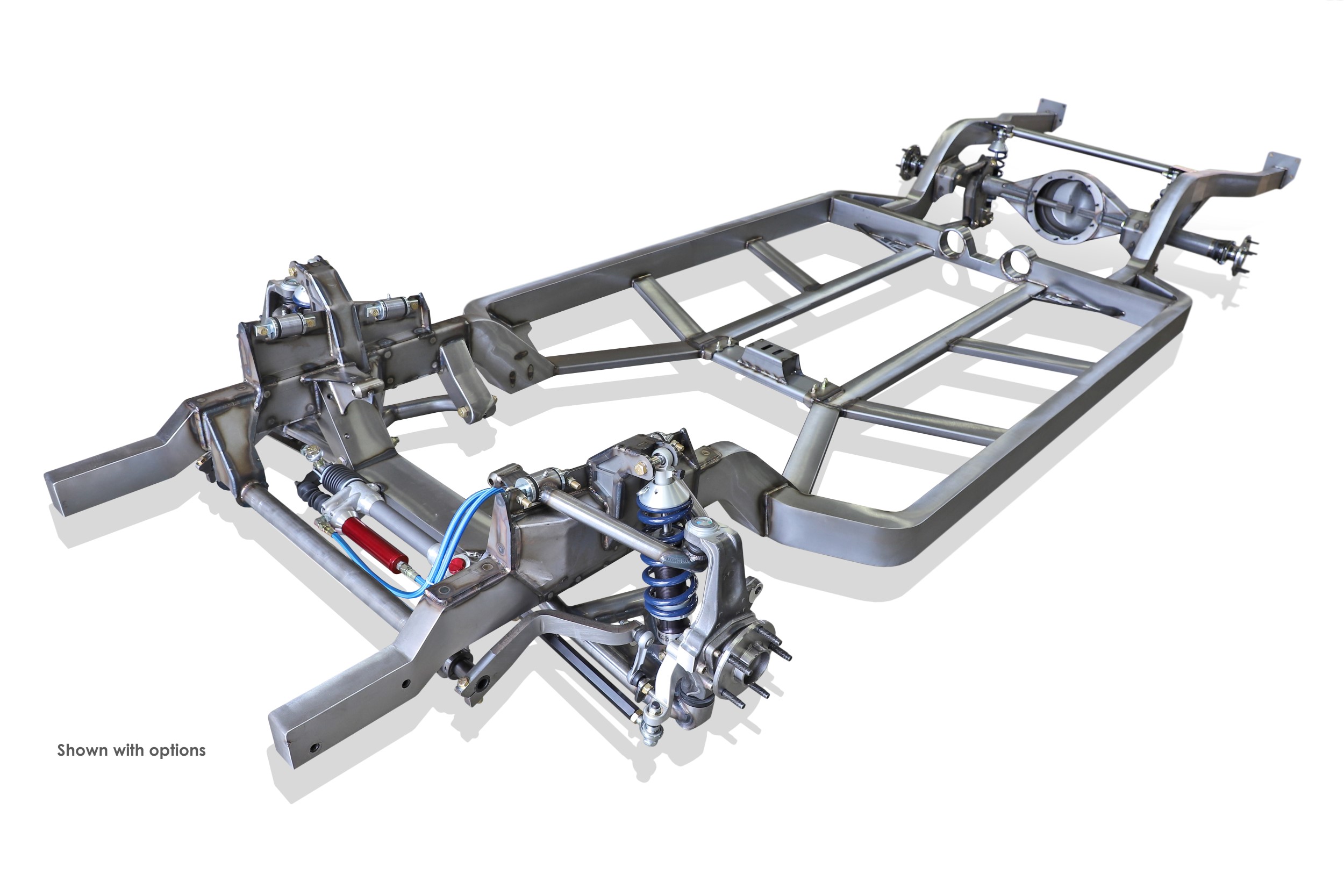

While others have chosen to keep the same antiquated suspension geometry and design, the Roadster Shop continues to raise the bar and break new ground with the debut of the new REVO IFS Chassis for 1949-51 Mercury. The REVO IFS is exactly what its name suggests, a revolution in independent front suspension design, geometry, technology, and construction.

The REVO IFS has been created from the ground up, leaving behind the antiquated Mustang II geometry and ride quality where it firmly belongs: in the past. Controlled roll centers, eliminated bump steer, and CAD optimized camber and caster curves provide a suspension that offers the absolute best combination of ride quality and street performance. With 5.5″ of wheel travel and positive and negative bump stops, the REVO front end allows smooth articulation through the full range of motion, creating the most comfortable, balanced and street friendly dynamics possible within this package.

The REVO front end has been designed from scratch using the latest CAD development software and design processes. 115 unique components were designed and manufactured for this suspension, allowing a fresh design template to build the ultimate IFS without compromise. Keeping with the latest manufacturing processes to raise quality while controlling costs; laser, plasma, CNC milling and turning are all employed in the manufacturing of these components. With a years worth of in house development, the REVO IFS has been fine-tuned and streamlined to redefine the standard for street performance suspension.